Ilensi ye-Acrylic, i-PMMA ilensi yePlastiki.

Isingeniso selensi:

I-base plate ye-acrylic lens yenziwe nge-PMMA, ebizwa nangokuthi ilensi ye-acrylic ecindezelwe ngabantu baseHong Kong naseTaiwan.Ilensi ye-Acrylic ibhekisela epuleti le-acrylic elikhishiwe.Ukuze kuzuzwe i-electroplating yebanga le-optical, ipuleti lesisekelo lizokwenza umphumela wesibuko ngemuva kokumbozwa kwe-vacuum.I-lens yepulasitiki isetshenziselwa ukufaka esikhundleni se-lens yengilazi, enezinzuzo zesisindo esincane, akulula ukuphuka, ukubunjwa okulula nokucubungula, ukufaka imibala okulula nokunye, umfutho wokuthuthukiswa ukhuphuka usuku nosuku, futhi usuphenduke uhlobo lobuchwepheshe. ekukhiqizweni kwamalensi.Amapuleti epulasitiki ngokuvamile angenziwa: isibuko esinohlangothi olulodwa, isibuko esinezinhlangothi ezimbili, isibuko sepulasitiki, isibuko sephepha, i-lens eyingxenye, njll. zingenziwa ngokuvumelana nezidingo ezahlukene.Isibonelo, isikrini sefoni ephathekayo ne-TV singabonakala nsuku zonke.

Izici zamalensi:

I-Acrylic ilungele ukucutshungulwa kwesibili, njengokusebenza kwemishini, ukubumba kwe-thermoplastic, ukubumba i-blow, i-blister, i-solvent bonding, ukuphrinta okushisayo, ukuphrinta kwesikrini kanye ne-vacuum electroplating.Ngemuva kwempumelelo, yilokho esikubiza ngokuthi i-acrylic lens.

Ipuleti le-Acrylic lenziwe nge-polymerized nge-methyl methacrylate monomer (MMA), okuyi-polymethylmethacrylate (PMMA) plate plexiglass, okuwuhlobo lwe-plexiglass ecutshungulwa inqubo ekhethekile.Inegama elithi "indlovukazi yepulasitiki".Ucwaningo nokuthuthukiswa kwe-acrylic kunomlando weminyaka engaphezu kwe-100.

Ukusebenzisa ilensi:

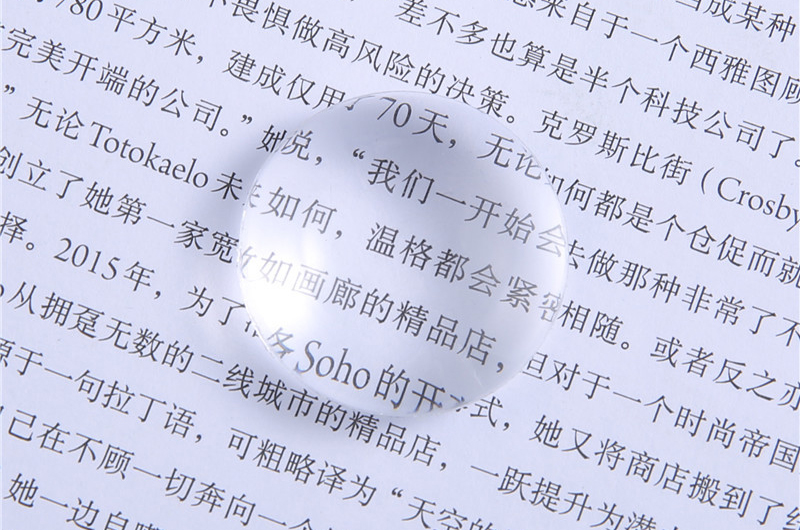

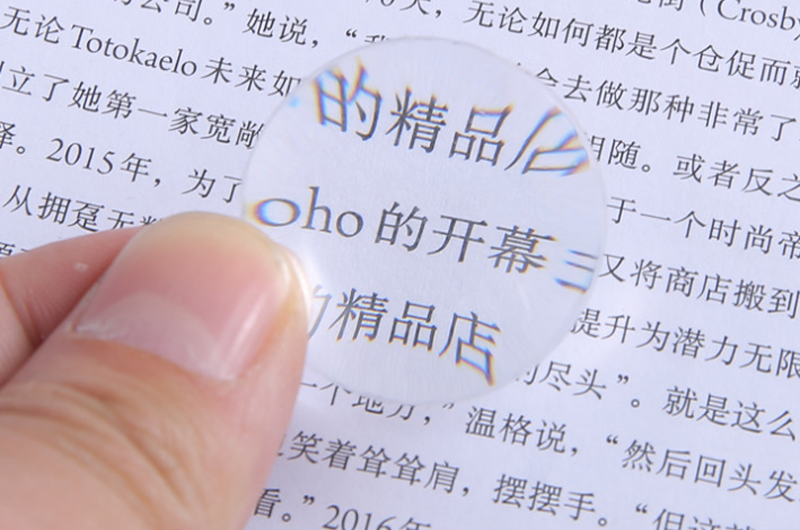

I-Acrylic inezinzuzo zesisindo esincane, intengo ephansi kanye nokubumba okulula.Izindlela zayo zokubumba zihlanganisa ukuphonsa, ukubumba umjovo, umshini, i-acrylic thermoforming, njll. Ikakhulukazi, ukubunjwa komjovo kungakhiqizwa ngobuningi, ngenqubo elula nezindleko eziphansi.Ngakho-ke, isetshenziswa kabanzi ezingxenyeni zensimbi, amalambu emoto, amalensi optical, amapayipi asobala nokunye.

I-Acrylic iyinto entsha engcono kakhulu yokwenza izinto zangasese ngemuva kwe-ceramics.Uma kuqhathaniswa nezinto ze-ceramic zendabuko, i-acrylic ayinayo kuphela ukukhanya okuphezulu okungenakuqhathaniswa, kodwa futhi inezinzuzo ezilandelayo: ukuqina okuhle futhi akulula ukulimaza;Ukubuyisela okunamandla, inqobo nje uma igwebu elithambile elicwiliswe ku-toothpaste lingakwazi ukusula i-sanitary ware entsha.Ukuthungwa kuthambile, futhi akukho ukuzwa kwethambo ebusika;Imibala ekhanyayo ingahlangabezana nokuphishekela komuntu ngamunye okuthandayo okuhlukile.Isitsha setafula, ubhavu kanye nendlu yangasese eyenziwe nge-acrylic ayiyona nje into enhle ngesitayela, ihlala isikhathi eside, kodwa futhi ihambisana nemvelo.Umzila wayo wemisebe ucishe ufane nowamathambo abantu.Impahla ye-Acrylic sanitary yaqala ukuvela e-United States futhi manje ibalelwa ngaphezu kwama-70% emakethe yamazwe ngamazwe.Ngenxa yobunzima nezindleko eziphakeme zokukhiqiza i-acrylic, kunezindawo eziningi ezingabizi kakhulu ezithatha indawo emakethe.Lezi ezithatha indawo, ezaziwa nangokuthi “i-acrylic”, empeleni ziyibhodi elivamile lezinto eziphilayo noma ibhodi eliyinhlanganisela (elibuye laziwe ngokuthi i-sandwich board).Ibhodi elijwayelekile le-organic lisakazwa ngezinto ezijwayelekile zokuqhekeka kwe-plexiglass kanye nombala.Ukuqina kwayo kwendawo kuphansi futhi kulula ukufiphala.Umphumela wokupholishwa mubi ngemva kokupholishwa ngesihlabathi esihle.Ibhodi eliyinhlanganisela linongqimba oluncane lwe-acrylic kuphela phezulu kanye nepulasitiki ye-ABS phakathi.Kulula ukwehlisa ngenxa yethonya lokwanda okushisayo kanye nokuncipha okubandayo okusetshenziswayo.I-acrylic yeqiniso nengamanga ingabonakala kusukela kumehluko wombala ocashile nomphumela wokupholisha wesigaba samapuleti.1 Uhlelo lokusebenza lwezokwakha: iwindi, umnyango nefasitela elingazwakali, ikhava yokukhanya emini, idokodo locingo, isibuko sombala wokuhlobisa, njll Isicelo sokukhangisa: ibhokisi elikhanyayo, ibhodi lezimpawu, ibhodi lezimpawu, indawo yombukiso, njll Isicelo sezokuthutha: isitimela, isibuko esihlehlisa imoto, ilensi yemoto, njll. 4 Isicelo sezokwelapha: i-incubator yengane, amathuluzi okwelapha okuhlinza ahlukahlukene, izinto ezisetshenziswa umphakathi: imisebenzi yezandla, izibuko zezimonyo, abakaki, izindawo ezihlala emanzini, izibuko zokudlala, njll. Uhlelo lwemboni: iphaneli yensimbi nekhava, njll. Izinhlelo zokusebenza zokukhanyisa: isibani se-fluorescent, i-chandelier, ikhava yesibani somgwaqo, i-led i-reflector, i-acrylic reflector, njll.

Izici zenqubo:

1. I-Acrylic iqukethe i-polar side methyl, ene-hygroscopicity esobala.Ukumuncwa kwamanzi ngokuvamile kungama-0.3% - 0.4%.Kumele kube ipuleti le-acrylic ngaphambi kokwakhiwa

Kumele yomiswe ngaphansi kwesimo sika-80 ℃ - 85 ℃ amahora angu-4-5.2. I-Acrylic inezici ezisebenzayo nezisobala ezingezona ze-Newtonian ebangeni lokushisa lokucubungula ukubumba.I-viscosity encibilikayo izokwehla kakhulu ngokunyuka kwezinga le-shear, futhi i-viscosity yokuncibilika nayo izwela kakhulu ekushintsheni kwezinga lokushisa.Ngakho-ke, ukuze kusetshenziswe ukubunjwa kwe-polymethylmethacrylate, ukwandisa ingcindezi yokubumba kanye nezinga lokushisa kunganciphisa kakhulu i-viscosity encibilikayo futhi ithole uketshezi olungcono.3. Izinga lokushisa i-acrylic eqala ngalo ukugeleza lingaba ngu-160 ℃, futhi izinga lokushisa lapho iqala ukubola lingaphezu kuka-270 ℃, nebanga lokushisa elibanzi lokucubungula.4. I-viscosity ye-acrylic melt iphezulu, izinga lokupholisa liyashesha, futhi imikhiqizo kulula ukukhiqiza ukucindezeleka kwangaphakathi.Ngakho-ke, izimo zenqubo zilawulwa ngokuqinile ngesikhathi sokubunjwa, futhi imikhiqizo nayo idinga ukwelashwa ngemva kokubunjwa.5. I-Acrylic iyi-polymer e-amorphous ene-shrinkage encane kanye nobubanzi bayo bokuhlukahluka, ngokuvamile mayelana no-0.5% - 0.8%, okulungele ukwenza izingxenye zepulasitiki ezinobuncane obuphezulu.6. Ukusebenza kokusika kwe-Acrylic kuhle kakhulu, futhi iphrofayili yayo ingenziwa kalula ngamasayizi adingekayo ahlukahlukene.

Ukucubungula ubuchwepheshe:

I-Acrylic ingathatha ukubunjwa, ukubumba umjovo, i-extrusion, i-thermoforming, i-laser eqoshiwe, ukusika kwe-laser nezinye izinqubo.

Ukubunjwa kokusakaza

Ukubunjwa kwe-Casting kusetshenziswa ukwenza amaphrofayili afana namapuleti e-plexiglass nemigoqo, okungukuthi, amaphrofayili akhiwa nge-polymerization ngobuningi.Imikhiqizo ekhonjiwe idinga ukwelashwa ngemuva.Izimo zangemuva kokwelashwa ukugcinwa kokushisa kwe-2h ku-60 ℃ nokugcina ukushisa isikhathi esingu-2h ku-120 ℃.

Ukubumba umjovo

Ukubumba komjovo kusebenzisa i-granular material elungiselelwe i-polymerization yokumiswa, futhi ukubunjwa kwenziwa emshinini wokubumba ojwayelekile we-plunger noma ngesikulufa.Ithebula 1 libonisa izimo zenqubo evamile yokubumba umjovo we-polymethylmethacrylate.Inqubo nemingcele isikulufa umjovo ekubumbeni umshini iplunger umjovo wokubumba umgqomo womshini ℃ izinga lokushisa elingemuva 180-200 180-200 maphakathi 190-230 phambi 180-210 210-240 nozzle lokushisa ℃ 180-210 210-240 4 umjovo isikhunta 0-80 4 umjovo 4-80 ℃ ingcindezi MPa 80-120 80-130 ebambe ingcindezi MPa 40-60 40-60 isikulufa isivinini rp.m-1 20-30 imikhiqizo umjovo futhi badinga post-ukwelashwa ukuqeda ukucindezeleka kwangaphakathi, Ukwelashwa Kwenziwa 70-80 ℃ umoya oshisayo wokoma ihhavini.Isikhathi sokwelashwa sebha ye-acrylic ngokuvamile sithatha cishe u-4H kuye ngobuningi bomkhiqizo.

I-Thermoforming

I-Thermoforming inqubo yokwenza ipuleti le-plexiglass noma ishidi libe yimikhiqizo enosayizi nobujamo obuhlukahlukene.Ukusikwa okungenalutho kusayizi odingekayo kuboshwe ohlakeni lwesikhunta, kushiswe ukuze kuthambe, bese kucindezelwa ukulenza lisondele endaweni yokubumba ukuze kutholwe isimo esifanayo nesikhunta.Ngemuva kokupholisa nokubunjwa, unqenqema luyasikwa ukuze kutholwe umkhiqizo.Indlela yokudweba i-vacuum noma i-pressurization eqondile ye-punch ngephrofayili ingamukelwa ngokucindezela.Izinga lokushisa le-thermoforming lingabhekisela ebangeni lokushisa elituswayo kuThebula 3. Uma usebenzisa imikhiqizo yokwakha okusalungiswa kwe-vacuum esheshayo, kuyafaneleka ukwamukela izinga lokushisa eliseduze nomkhawulo ophansi.Lapho wenza imikhiqizo ejulile yokusalungiswa enomumo oyinkimbinkimbi, kufanelekile ukwamukela izinga lokushisa eliseduze nomkhawulo ongaphezulu.Ngokuvamile, izinga lokushisa elivamile liyamukelwa.

Sinawo wonke usayizi we-Arylic lens, uma uwadinga, sicela usithinte ngomusa, singakwazi nokwenza ilensi ye-Arylic ngokwesidingo sakho.Ungathumela umdwebo kithi, ngakho-ke, singakwenzela isikhunta.Ngiyabonga kakhulu.